(Last updated on January 9th, 2023)

AutoCAD or Fusion 360, which is better? What are the differences between AutoCAD and Fusion 360?

These two programs are quite different from one another, and as you read on, you will see that they serve entirely different purposes. Which one should you pick? The answer will be easy after we have given you a detailed understanding of the two programs.

- AutoCAD Basics

- Fusion 360 Basics

- General Differences between Fusion 360 and AutoCAD

- Three Major Differences Between AutoCAD and Fusion 360

- AutoCAD Vs Fusion 360: Side-By-Side Comparison

- Short Verdict

- Get up to 70% Off on Top Products!

- In-Depth considerations

- Fusion 360 Cloud Credits

- Fusion360, the Process in a Nutshell

- Summary

If you are considering choosing between these two CAD apps for your goals, then you will be pleased to know that the significant differences between the two will make this a natural choice. However, if you’re looking for a more comparable software to AutoCAD, then try comparing it to Vectorworks.

Fusion 360 is unique versus many other CAD offerings I’ve reviewed so far. I will go over the details of those differences later in the article.

AutoCAD Basics

AutoCAD, released in the late 1980s, is a computer-based drafting program. In the old days, you had to type in all the coordinates of the lines and points to draw blueprints. Over time, AutoCAD has evolved into a much smoother and user-friendly drafting software.

It is effortless to use once you get the hang of the different commands and shortcuts. In the past two decades, AutoCAD has developed 3D modeling capabilities, but it is far from the industry-leader in 3D drafting. Autodesk is the company that has developed AutoCAD as well as Fusion 360 and many other CAD applications.

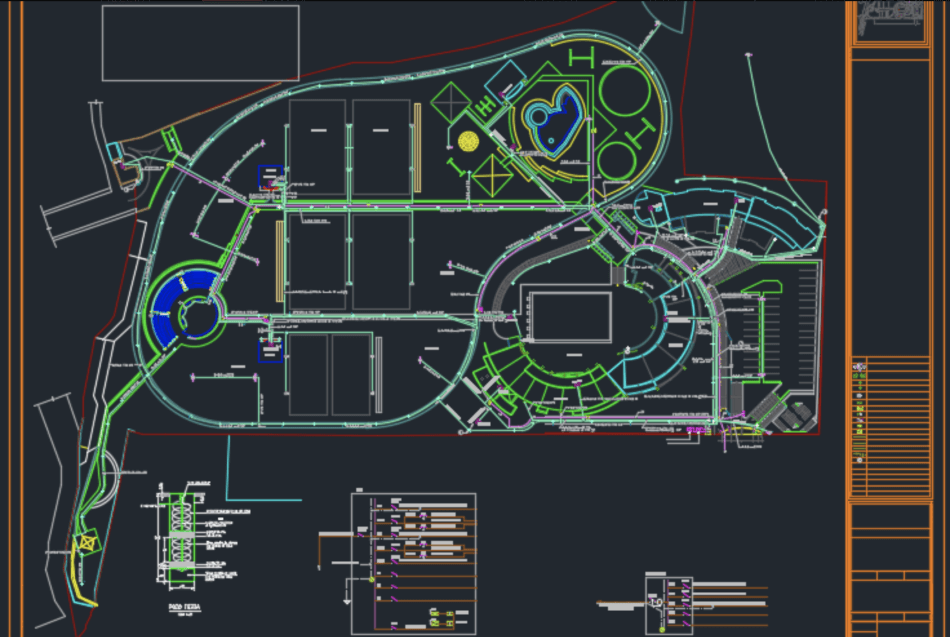

(Below: AutoCAD 2D drafting)

Fusion 360 Basics

Fusion 360 is a “CAD in the Cloud” application that is easy to use, yet powerful enough to develop professional products. The idea was to create a platform to host complex CAD models of new products for professionals to collaborate remotely. Different members of the same team can access the same model and modify it easily.

Professionals from across the globe can work as if they are in the same office building. Fusion 360 seems much more straightforward than Autodesk Inventor (see our comparison with AutoCAD), but it is potent, once you understand the tools. While the tools may be a little different than a program such as Inventor, you will be surprised to find out that you can model just about anything in Fusion 360.

General Differences between Fusion 360 and AutoCAD

Autodesk developed both platforms, AutoCAD being the original poster child for Autodesk. In the past couple of decades, we have seen a slew of new products come out of the minds of Autodesk’s developers.

Think of AutoCAD as the granddad of the Autodesk family. You can think of Fusion 360 as one of the new little grandbabies. As different industries used AutoCAD and other more basic drafting programs, they started to request tools to make their jobs easier. So, for instance, Autodesk produced Civil3d, specialized software for civil engineers.

AutoCAD is what you might call “dumb geometry.” When you draw a line in AutoCAD, it doesn’t know whether it is representing a wall, a contour line, a plastic part, a door, a window, etc. CAD programs are becoming more and more integrated with reality and are simulating actual conditions of the thing they are drawing.

That’s a big wordy mouthful just to say, “The more advanced CAD becomes, the more it will match reality.” I’ll go into more detail on the significant differences in later sections.

Three Major Differences Between AutoCAD and Fusion 360

- AutoCAD is “dumb geometry,” while Fusion 360 is more dynamic and capable of simulating the product’s physics.

- Fusion 360 has an emphasis on “Cloud-Based Hosting.”

- Fusion 360’s more advanced features require “Cloud Coins” on an as-needed basis (which means added cost)

AutoCAD Vs Fusion 360: Side-By-Side Comparison

| Criterion | AutoCAD | Fusion360 | Notes |

| Price | N/A | N/A | Depends (see below) |

| Customer Service | Tie | Tie | |

| User Experience | Tie | Tie | |

| Learning Curve | Tie | Tie | |

| Capabilities | N/A | Winner | |

| CAD/CAM | N/A | Winner | |

| Rendering | Tie | Tie | |

| Simulation | N/A | Winner | |

| Assembly | N/A | Winner |

Short Verdict

AutoCAD is a computer-based general-purpose CAD software, used for drafting 2D drawings and simple 3D models, whereas Fusion 360 is a “CAD in the Cloud” application, with a strong emphasis on product development and simulating real-world conditions for product models. Fusion 360 offers remote collaboration for professionals, whereas AutoCAD doesn’t.

It doesn’t make much sense to put AutoCAD and Fusion 360 in a proverbial “boxing ring” and see which one is better, because they are fundamentally different. Generally speaking, AutoCAD is a multi-functioning general-purpose CAD software program. Whereas Fusion 360 has a strong emphasis on developing products.

It refines these products to depict real-world conditions through computer simulations. Virtual R&D is less expensive than going through several iterations of prototypes to see if they can handle typical stresses.

When it comes to a “short verdict,” there isn’t one unless you judge them by a particular criterion. If I’m judging which of the two is better for the general drafting of simple drawings and 3D models, then AutoCAD is the winner in my book. If you are specifically looking to develop a new product and test its capabilities virtually, then Fusion 360 is your winner.

If you just need 2D drafting versus 3D, then stay away from AutoCAD and Fusion 360 altogether and give AutoCAD LT a shot (“LT” stands for Limited Technology).

For this article, however, let’s break some things down and judge these two based on the criterion of “Which of these is better for developing an invention, machine, or product?”

Get up to 70% Off on Top Products!

Autodesk

See the latest Autodesk deals, discounts, promotions, and bundled packages. Save up to 70% on top products!

at autodesk.com

AutoCAD

AutoCAD is one of the most powerful 2D and 3D CAD software out there.

at autodesk.com

Fusion 360

Fusion 360 is a cloud-based CAD/CAM/CAE software for product design.

at autodesk.com

In-Depth considerations

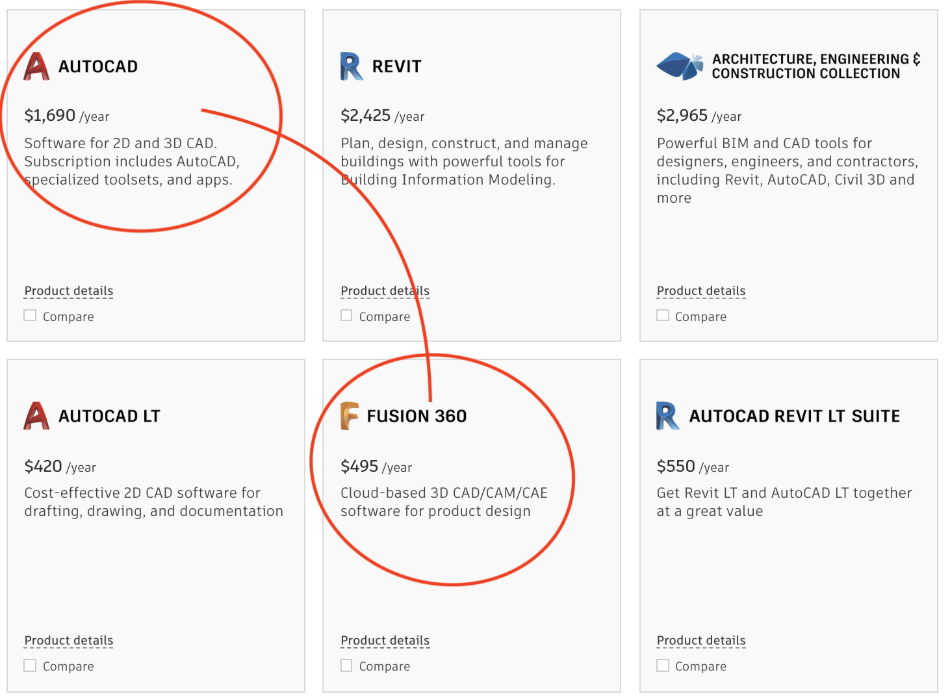

1. Price

| Product | Regular Price | Discounted Price |

| AutoCAD | $1,690/year | Check here |

| Fusion 360 | $495/year | Check here |

| Autodesk Deals & Packages | varies | Check here |

Winner: Depends… (seems like a weird verdict, but you need to read below to understand!)

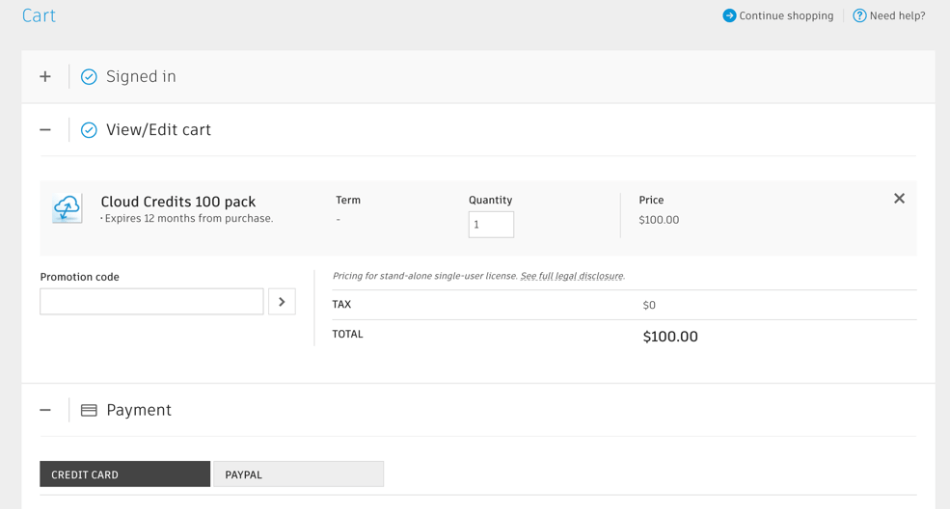

Listen! I find it very important that you read this section. If you aren’t aware of the Cloud-Based-Services that are part of Fusion 360, then you may be in for a rude awakening. Here’s why; (See image below)

At first glance, Fusion 360 looks like a great deal, considering everything it can do. However, several of Fusion 360s more distinguishing services are NOT included in the monthly subscription fee. Were you expecting to be able to utilize the CAM simulator or the Annotative Design feature?

You certainly can, for a nominal fee! For more details regarding the cost of the Cloud Credit services, look at the section entitled Fusion 360 Cloud Credits.

Let’s be fair and look at things from the other side. If you need to render a complex model and your computer would take 20 hours to render, it would undoubtedly be well worth the Cloud Credits to have Autodesk’s servers render it for you via the cloud. See? Hidden fees aren’t always a bad thing, are they?

That being said, let’s break down the cost of AutoCAD vs. Fusion 360

- Free Trial (Yes for both programs)

- Student Edition (Free for both programs)

- Hobbyist Edition (Free for Fusion 360…? Yes! You heard correctly! If you want to use Fusion360 just for fun and not for commercial use, then go ahead and use it. When your free trial ends, it will still be available for use.)

- Subscription Fee:

- Fusion360 costs $60/month – $495/year – $1,335/year

- AutoCAD costs $210/month – $1690/year – $4,565/year

2. Customer Service

Winner: Tie

Autodesk owns both, so you can expect the same level of customer service with both applications.

3. User Experience

Winner: Tie

In many ways, comparing how the two UI’s operate is liking comparing apples to oranges. Overall, they both strive to be user friendly. You have the same typical workspace with the three axes (x,y,z) and a lot of buttons and option menus.

AutoCAD has the classic “command line” (which I love), and Fusion 360 has a contextual “right-click” menu, which can be useful for saving time and improving workflow. Fusion 360 tends to be “intuitive” in many ways. It recognizes what you are doing and will often bring up a contextual menu with functions you are likely to use next. Very cool!

(Below; Fusion360 UI)

4. Learning Curve

Winner: Tie

If you are asking, “Which of these programs is easier to learn?” Then the answer, as far as I am concerned, is “neither.” Why? The simple answer is that whether you only need the more essential functions or the most complex functions, you need to put effort into learning how they work. I am tempted to say that AutoCAD is the easier of the two because the most advanced functions of Fusion 360 might require an engineer’s level of expertise.

On second thought, the question isn’t whether or not the software is complicated, but whether or not, given the user understands their field of expertise, which of the two is easier to learn. Taking that into consideration, many different kinds of professionals use these programs for their purposes. Assuming you know your profession, either of these programs will require a decent amount of effort and energy to learn.

So do yourself a favor and stop worrying about how easy or difficult it is to learn! Set your mind to learning, and you will.

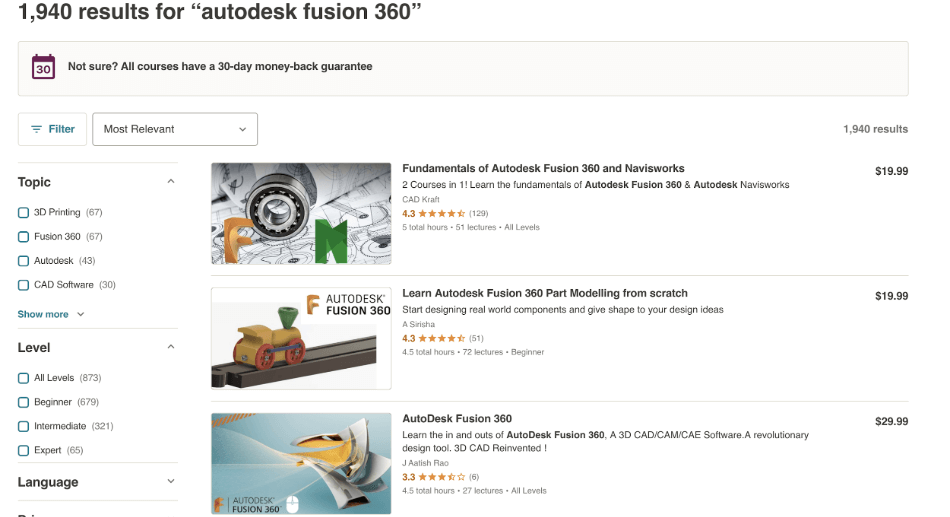

(Below: Udemy Fusion360 Courses)

5. Capabilities

Winner: Fusion 360

Both AutoCAD and Fusion 360 can produce 3D models of all shapes and sizes, but there are some things Fusion360 can do that AutoCAD simply can’t. Here’s a short list:

1) Standardized bolt hole tool

2) Applying materials to shapes

3) Stress testing those materials for real-world conditions

4) AI-based part design (Yes, we are getting to the point where AI can design parts for us…scary, but true.)

5) A slew of product-development-specific predictive tools in the UI

6. CAD/CAM

Winner: Fusion 360

Specific machines such as steel cutters, waterjets, 3D printers, and lathe machines can all be programmed to run off of a CAD drawing. For a water jet, the file can be a simple DWG drawing that tells the computer where to cut its lines.

It needs a file format that it can convert into its physical operations. The same is true for 3D printers; they use STL files. AutoCAD and Fusion360 can both produce STL files. Depending upon what machine you’re using, either one of these programs can likely be used, but DWG files (AutoCAD’s format) are more common for such machinery.

Fusion360 can simulate how a CAM machine might cut a 3D part out of the raw material. Keep in mind; this is another Cloud Credit service. (See Fusion 360 Cloud Credits section below for a few more details)

Fusion 360 has a menu of industry-standard CAMs that can replicate the real-life process to predict potential manufacturing problems before they happen.

7. Rendering

Winner: Tie

AutoCAD and Fusion360 can both produce some impressive photorealistic renderings. Renderings are critical when it comes to showing off. It may not seem important to you, but you need to consider that the best professionals in their business are going to push the envelope in every way they can to present their product as the best of the best.

It is an inescapable principle; showmanship is part of developing a product. No matter what you are producing, salesmanship, and showmanship is always going to be a critical factor.

I need to point out that if you want to “render on the cloud” via Fusion 360, you will need to pay an extra fee. Fusion 360 can render via your local hardware, but the cloud-based service is more advanced and powerful and would probably go faster. For more details, view the section entitled Fusion360 Cloud Credits.

(Below; Fusion360 Rendering)

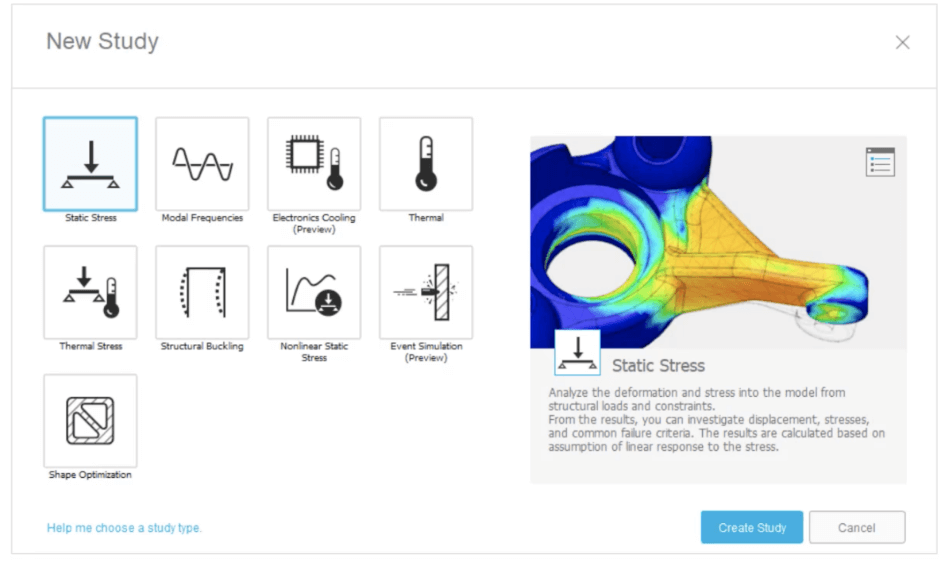

8. Simulation

Winner: Fusion 360

AutoCAD can’t even run stress simulation, so the winner here is clear. Unless plug-in software is available that I’m not aware of, Fusion 360 is the winner in this category. Running this kind of simulation requires that you apply material qualities to the 3D model.

These material qualities include tensile strength, fracture strength, pliability, thermal resistance, etc. Simulation models can calculate how much force it would take to break the part, so you can put all the parts of your product together and then put the anticipated stresses on your product to find the “weakest link.”

(Below: Fusion360 Simulation Options)

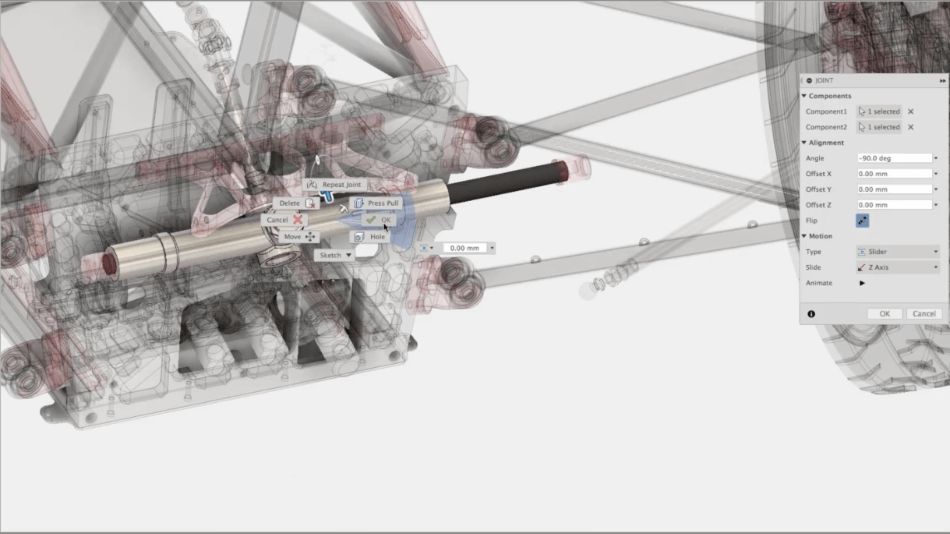

9. Assemblies

Winner: Fusion 360

As I’ve stated before, many CAD programs are starting to blur the lines between the virtual model and the real-world product. A powerful example is assigning relationships and constraints between parts in a 3D model.

You may, for example, build all the individual components of an engine and put them together into a single 3D model. Use Fusion 360 to assign relationships between these parts.

For example, you can place an engine together, and after programming the physical relationships of the 3D parts, you can watch the engine spin and function just like it would in real life.

(Below: Fusion360 Assembly)

Fusion 360 Cloud Credits

As I’ve stated before, in previous sections, Fusion 360 requires Cloud Credits to execute some of its more advanced functions. Currently, one Cloud Credit = 1 USD. Some of Fusion360’s services are performed using Autodesk’s cloud servers.

Using these features require Cloud Credits. When you consider the cost of AutoCAD or Autodesk Inventor, it may still be worthwhile to use some of these features from time to time. Also, a subscription to Fusion 360 comes with a certain number of Cloud Credits.

USD 1 = 1 Autodesk Cloud Credit

Rendering = 1+ credits per render (depending on how complex the model is)

Running Simulation = 5 credits ea.

Structural Buckling Simulation = 15 credits ea.

Nonlinear Static Stress Simulation = 25 credits ea.

Other advanced services are pay-as-you-go, so this is just a short list to give you an idea.

Fusion360, the Process in a Nutshell

If you want to produce a new product these days, whether that is a car, a cell phone case, a computer mouse, an unmanned drone, etc., then here’s the process that can be used for developing in a program like Fusion360.

Instead of starting in Fusion360, you begin with ideas written on paper. Coffee Shop napkins are notorious for recording great ideas. When inspiration strikes, you don’t need a sophisticated machine to write them down.

After you develop a rough idea, you need to get more specific. Many products these days are a combination of art and engineering. The initial technical drawings may be artistic sketches as well as more detailed schematics. The reason you want to brainstorm these aesthetic and functional details outside of your CAD program is to have the freedom and creativity to produce something truly unique.

After developing the features to the point where you have specific technical measurements as a guide, you jump into Fusion 360 and start modeling the product’s parts. For a wireless computer mouse, for example, you would model the top section of the case, the side section, the bottom section, the mouse wheel, additional buttons, the battery compartment cover, the motion tracker, etc.

(Thank God computer mice have evolved past the roller-ball. Some of you young folk may not know what that is.)

After modeling each of these parts, you assign a material to each piece. Materials in Fusion 360 have real-world attributes that the computer uses for calculating stress tests. After modeling the mouse parts, you open up an assembly, where you put all the pieces together. You can run some simulations to see how effective the mouse-buttons work and whether or not there’s enough room for the battery to fit.

Next, you can run some drop-tests to see if the mouse would survive a drop from shoulder height onto a hard surface. After you’ve tweaked things enough, you can send the file to the appropriate manufacturer for a prototype. After getting your prototype parts modeled, you can put them together to see if it works.

You’ll need to get the circuitry and software working correctly (which isn’t easy, so good luck with that!), but after all is said and done, you’ve just created a functioning wireless computer mouse from scratch. Congratulations!

Summary

With all things said and done, Fusion 360 is an amazing little program. There are many ways I can summarize this comparison, but let’s be super-simple; For 2D drafting, pick AutoCAD (or AutoCAD LT), but for 3D modeling of real-world products, choose Fusion 360.

Fusion 360 is intuitive, cloud-based, has a reasonably simple UI, but boasts professional-level capabilities. AutoCAD is the epitome of bread-and-butter CAD, whether 2D or 3D.

Chris Graham is an experienced Computer-Aided Design (CAD) draftsman and a writer. He has extensive knowledge of almost all the top CAD software available on the market these days. From simple tasks to developing a professional CAD drawing, he can do everything.

He also has a Bachelor of Architecture (B.Arch.) (Landscape Architecture & Civil Engineering) degree from the Louisiana State University School of Architecture and Design. He has worked at the Corporate Green Landscape Management where his duties included landscape design, irrigation design, landscape installation, CAD drafting.

Fusion 360 is more helpfully for making a product design, so i choose Fushion 360 Software